What is Pollen AM?

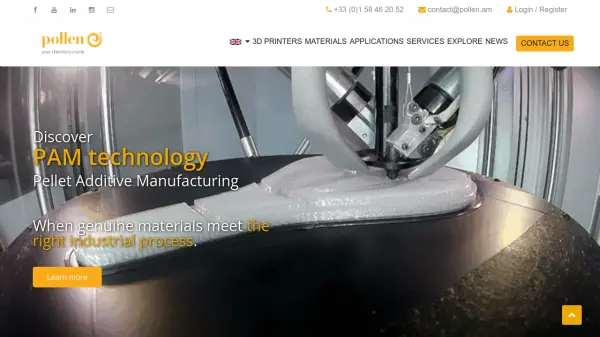

Pollen AM specializes in advanced pellet extrusion 3D printers designed to meet the precise requirements of industrial processes. Leveraging genuine industrial-grade pellets—including metals, ceramics, elastomers, and thermoplastics—these printing solutions allow businesses to achieve both high performance and significant cost savings. The open architecture gives users the flexibility to source materials independently, accommodating demanding applications in industries such as research, prototyping, and production.

Pollen AM's configurable software ecosystem, powered by open-source slicers, enables users to fine-tune material profiles and print parameters, supporting the production of high-quality, certified parts. With extensive support for multi-material printing and integration options, the platform is geared for innovation in research and development, manufacturing, and education.

Features

- Pellet Extrusion Technology: Directly uses industrial-grade pellet materials for printing.

- Material Flexibility: Compatible with thermoplastics, metals, ceramics, and elastomers.

- Multi-Material Printing: Supports up to 4 extruders for complex, multi-material parts.

- Open Software Ecosystem: Utilizes open-source Cura-based slicer for custom material profiles.

- Heated Chamber and Radiant Disk: Enables processing of demanding, high-performance materials.

- Industrial Integration: Configurable systems for seamless adaptation to industrial workflows.

- Certified Parts Production: Prints components that meet flame-retardant, medical, and other certifications.

- Cost-Efficiency: Significantly lowers material costs by using raw industrial pellets.

Use Cases

- Rapid prototyping of complex industrial components.

- Material research and validation in academic or corporate R&D.

- Small and medium batch production of end-use parts.

- Manufacturing tools, fixtures, or spare parts using certified materials.

- Developing multi-material prototypes for the sportwear or automotive industries.

- Educational applications in teaching additive manufacturing processes.

FAQs

-

What types of materials are compatible with the Pollen AM 3D printers?

Pollen AM 3D printers are compatible with a broad array of industrial pellet materials, including thermoplastics, metals, technical ceramics, and elastomers. -

Can I use third-party pellet materials with Pollen AM printers?

Yes, the open system supports user-sourced pellets, giving users flexibility to choose materials that fit their specific needs and certifications. -

Is the slicing software customizable for special applications?

The slicing software is open and based on Cura, allowing users to define and adjust material profiles and print parameters for specialized requirements. -

Does Pollen AM provide support for integrating printers into existing industrial workflows?

Yes, Pollen AM systems are configurable and can be integrated into various industrial environments upon request. -

Do the 3D printers support multi-material printing?

Pollen AM printers can be equipped with up to 4 extruders, enabling advanced multi-material printing capabilities.

Helpful for people in the following professions

Pollen AM Uptime Monitor

Average Uptime

100%

Average Response Time

116.5 ms

Featured Tools

Join Our Newsletter

Stay updated with the latest AI tools, news, and offers by subscribing to our weekly newsletter.