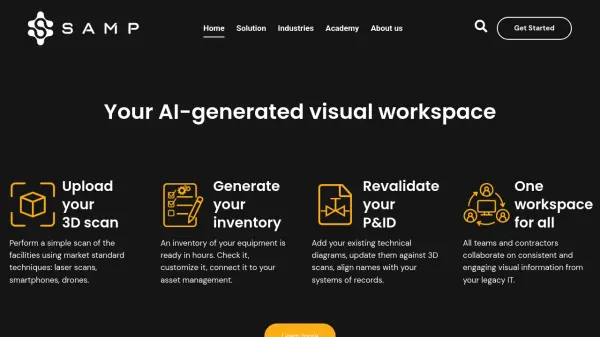

What is Samp?

Samp offers a "Shared Reality" platform, an AI-generated visual workspace specifically designed for industrial environments. It integrates 3D reality capture data, acquired through standard methods like laser scans, smartphone imagery, or drone footage, with existing technical documentation and asset management systems. This integration enables users to automatically generate an inventory of site equipment, validate technical diagrams such as P&IDs against the actual 3D scans, and ensure naming conventions align with established systems of record. The outcome is a centralized workspace allowing all relevant teams and external contractors to collaborate effectively using consistent, up-to-date visual information sourced from legacy IT infrastructures.

The platform is engineered to tackle prevalent challenges within industrial settings, notably the issues arising from outdated, incomplete, or hard-to-find technical information. By continuously linking 3D scan data with technical specifications, Samp assists in pinpointing inconsistencies, identifying previously uncataloged 'orphan' equipment, and rapidly updating site information to reflect current conditions. This capability supports enhanced decision-making processes for modification projects, maintenance activities, and overall site management, contributing to improved safety protocols, operational efficiency, increased plant availability, and more predictable financial outcomes throughout the entire lifecycle of an industrial asset.

Features

- AI-Generated Visual Workspace: Creates a shared reality platform from 3D scans.

- Automated Equipment Inventory: Generates equipment lists from uploaded 3D scans within hours.

- P&ID Revalidation: Allows comparison and updating of technical diagrams against 3D scans.

- Data Integration: Connects 3D visualization with existing systems like P&IDs, CMMS, document management, and data historians.

- Collaborative Platform: Enables teams and contractors to work with consistent visual data.

- Digital Twin Creation: Builds functional digital twins, even without existing 3D CAD models.

- Multi-Source Data Consolidation: Integrates maps, orthophotos, laser scans, photogrammetry, videogrammetry, and georadar data into a single viewer.

Use Cases

- Improving collaboration on modification projects and maintenance services.

- Identifying orphan equipment and inconsistencies in technical data.

- Updating technical information faster than site changes occur.

- Accelerating and securing collaboration between teams and contractors.

- Optimizing quotes and service contract execution for contract operators.

- Increasing plant uptime and reducing pre-visits.

- Enhancing safety and auditability in industrial operations.

- Revalidating or re-authoring PFD, P&ID, or isometric drawings.

- Optimizing tender processes and controlling contract amendments.

- Preparing equipment isolation (lock-out/tag-out) procedures safely.

- Providing full work context for inventories and work orders.

- Resolving claims using shared factual data.

- Setting up efficient punchlists and handover procedures.

- Carrying out inspections and walkdowns with complete information.

- Onboarding new and temporary workers quickly.

- Providing contextual access to legacy IT/OT data.

- Delivering digital twin as a service for engineering firms.

- Consolidating various field data types for scanning services.

Related Queries

Helpful for people in the following professions

Samp Uptime Monitor

Average Uptime

100%

Average Response Time

577.97 ms

Featured Tools

Join Our Newsletter

Stay updated with the latest AI tools, news, and offers by subscribing to our weekly newsletter.